Veneer, the thin sheet layer of wood

Veneer (wood veneer) is a thin sheet of wood. It is much used to layer the

m.d.f., particle board to produce wood looked surface. The veneer industry is

big scale in the woodworking industry. The wood veneers from any type of wood

are available in the market to supply the woodworking industry. If you need a

wood veneer then you can find supplier and order according to your need. But do

you know how wood veneer is made? In this article we want to share about the

process to make veneer.

Veneer is made from the wood, so the manufacture of veneer is started by cutting the tree. All types of tree can be used to make wood veneer, but usually the wood with nice looked are used. The nice exotic and expensive wood such as: ebony, rosewood, pavero, zebrano, etc. are used to make veneered panel with special wood looked. While the common wood such as: oak, pine, cherry, maples are also much used to make veneer. If the exotic woods are used to make special inlay in the wood looked panel, the common wood veneer are used to make the better wood looked panels. The wood veneer with high grade can be obtained with cheaper than the wood plank panels.

Veneer is made from the wood, so the manufacture of veneer is started by cutting the tree. All types of tree can be used to make wood veneer, but usually the wood with nice looked are used. The nice exotic and expensive wood such as: ebony, rosewood, pavero, zebrano, etc. are used to make veneered panel with special wood looked. While the common wood such as: oak, pine, cherry, maples are also much used to make veneer. If the exotic woods are used to make special inlay in the wood looked panel, the common wood veneer are used to make the better wood looked panels. The wood veneer with high grade can be obtained with cheaper than the wood plank panels.

The trees that are used to make

veneer should be long enough, has a straight trunk and quite big in the

diameter. The timber for veneer usually is better quality than the trees used

to make the wood panel. Some type of timber log is hard and brittle; it should

be soaked or boiled first before being sliced. Soaking the wood will make the wood

to be soft, elastic and reduce the problem in the slicing process. The tough

and brittle wood may need to be boiled to get soften.

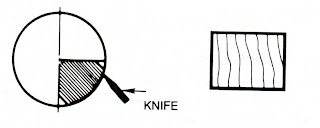

The wood stem is peeled by a rotary

knife to clean off the skin and sap wood to make the long wood trunk with same

size diameter from one end to the end. This log then is going to be sliced to

form veneer. There are various techniques of slicing: rotary slicing, flat cut slicing, half cut

slicing, quarter cut slicing and rift cut slicing. Each of cutting technique

will give different types of veneer and give the difference appearance in the

term of grain pattern. The different model of veneer slicing can be viewed below.

rift cut slicing

flat cut slicing

The next process is grading and

separating the veneers according to its quality. There are several grade of

veneer according to its quality. By length, the veneer is grouped into three:

the architectural grade, furniture grade and flooring grade. Architectural

grade, this is the longest veneer, up to 2.2 m - 3.4 meter length. It is used

to layer the specific forms of the building or home to make special architectural model. The

furniture grade is the veneer for the furniture industry.

Its size is according to make panels for furniture such as: side panels, top panels for

cabinet or table. Some special

furniture model that needs the longer veneer will need the architectural grade

veneer. The flooring grade is the shortest veneer with 1 meter length. It used

to make engineered flooring parquet, which is usually need the short panel.

The veneer is also graded according

to its defect as the wood panel. Veneer with a grade is the best quality; it is the veneer with

clean surface free from the eye, hole, crack and other defects. The B grade is the veneer with some defect or knot, if more defects are existed then the veneer is grouped in the C or D grade.

The architectural A grade veneer is

the most expensive, it means the veneer has clean and good surface for 3 meter

length. It is the sheet that first explored and separated from the bulk of the

sliced wood. The good performance sheet with some defect can be cut to go to

the furniture grade or flooring grade. The low performance veneer can also go

to the b grade or c grade. The A or B grade are used to make the face panel,

while the C or D grade can be used to layer the back panel or to be used as the

banded core.

Veneer storage.

As product from wood, the veneer is hygroscopic material that is susceptible to the changes of the air humidity. The changes in the environmental humidity will caused to the shrinkage or swelling that could damage the veneer. Therefore, the veneer should be stored in a conditioning room which has a stable humidity. In the room the veneer sheet with same quality, sizes and type are bundled and stored in the same place.

Applications and Uses

The wood veneer has widely used in the woodworking industry. It mostly used to make panel for any indoor uses. It has many advantages for panel making such as : more stable, more flexible and less expensive then the solid wood. With his advantage veneer has lot uses in woodworking industry such as: furniture, architectural product, door, floor, marquetry, and all other wood looked product

Stupendous blog you guys have provided there, I will absolutely valuate your effort.

ReplyDeleteclick over here