UV Coating for wood finishing

UV coating (ultra violet cured coating) coating that coating that dry with UV light with certain intensity. The coating contains a polymerized resin that will do the polymerization reaction with an energy ignition. When the coating is irradiated with the ultraviolet light with certain intensity, then free radicals accelerate polymerization reaction are generated. The coating is made of resins with photo initiator. The photo initiator is the material that work to trigger the chemical reaction to dry this chemical. The coating film resulted is a thermosetting layer that non dissolved, strong and hard. The ultra violet cured coating drying very fast, he need only few minute to be dry and produce hard coating.

The reaction

The curing reaction stimulated and catalyzed with ultraviolet radiation. The reaction mechanism is quite complex, but it can be simply described as follow:

There are 3 components required for the formation of film layers, polymerized resin, photo initiator and ultraviolet light. The resin is the material that will polymerize to create a layer of film. Photo initiator is a substance that absorbs radiation from the environment into the resin. The ultra violet light is the energy that a needed to initiate the reaction. When the photo initiator is exposed to UV light with sufficient intensity, then he will generate free radicals and trigger a polymerization reaction to make the coating to dry.

The resin material that used to make UV coating is usually oil free unsaturated polyester or acrylic. And the initiator is benzoin used for polyester and acetophenones for the acrylic. The UV coating will produce the hard and strong film coating in the finishing.

UV coating is developing rapidly very popular in the modern woodworking industry. It is the answer for the requirement to the finishing process which is more environmental friendly. The UV coating is very less in releasing the "expensive and pollutant" solvents. It also require little energy for drying and produce a very strong film layer. He give many advantages in the finishing industry.

- Strong, hard film layer

- The drying process is very fast, does not need big drying room

- End at relatively low cost compare with another coating.

- Friendly to the environment.

The material is made in high solid state less thinner and solvent. If the roller application is used, the material is made in around 98% solid content, with means no thinner and solvent released in the application. If the spray application is choose, then some thinner is needed to make is sprayable, but the thinner is sill much less with the other material finishing. It means less solvent release in application and less pollute to the environment.

While disadvantage of this coating are:

- This coating requires a series of machines an automatic spray and ultra-violet lamp that is expensive.

- Its uses is limited to a flat product.

The uses of the UV coating

- Finishing for wood flooring

The UV coating is the best coating for wood floor. The UV coating is widely used in the modern wood flooring manufacture to finishing his product. This coating is used to finish the wood parquet, wood veneer floor, laminated wood floor and other engineering wood floor. The coating produce the hard and strong film that is needed by flooring product.

- Flat furniture

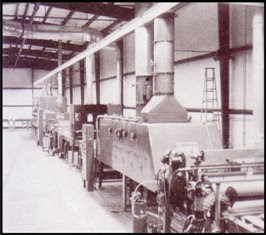

The UV coating is also most used to coat the flat furniture. The modern furniture with flat and panel from also uses lot of this coating. With the knock down construction, the furniture can be made in panels form. They are processed and produced and packed in panel form and assembled in the user location. The finishing process is done by flat line finishing line with UV coating material. The panel are inserted at one end to go through a series of finishing processes : paint application, drying and sanding and comes out at the other end with a dry finishing layer.

For some big product, the UV coating can be used to build the first film layer for the component. After the component are assembled then final coating is applied by spray with other finishing material : NC, AC or PU.

Post a Comment for "UV Coating for wood finishing"